- Coil Nails

- Jumbo Coil Nails

- Roofing Coil Nails

- Bulk Nails

- Concrete Nails

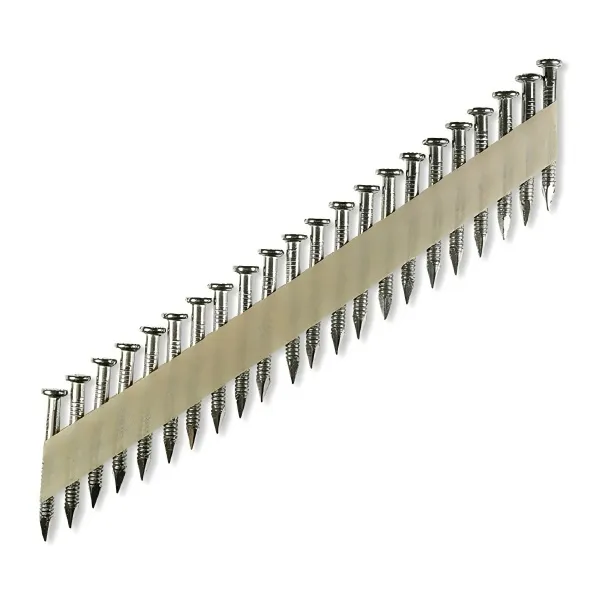

- Plastic Strip Framing Nail

- Paper Strip Framing Nail

- Wire Staples

- Aluminum Staples

- Stainless Staples

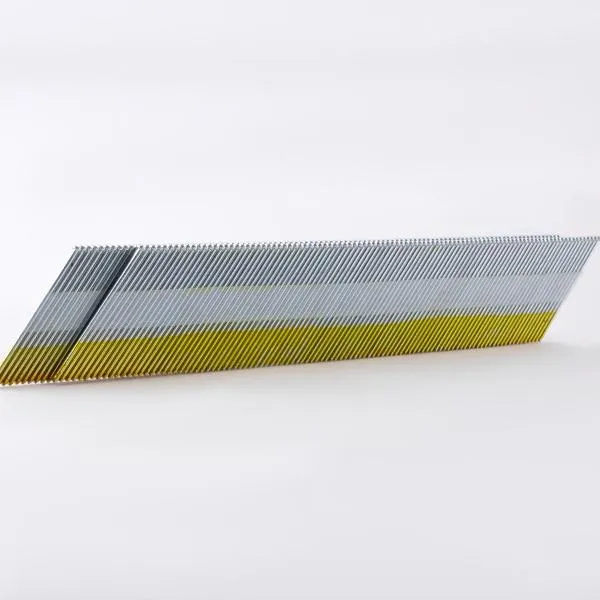

- Brad Nails

- Finishing Nails

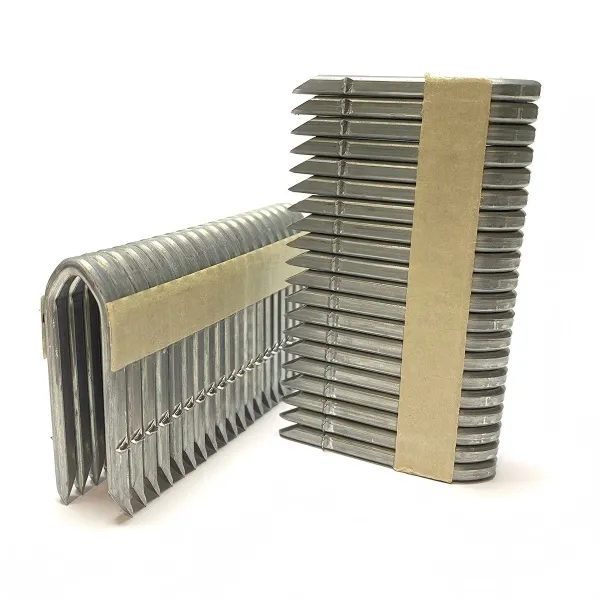

- Fence Staples

- Carton Staples

- Roll Staples

- U Shaped Staple

- Joist Hanger Nails

- Pin Nails

- Hog Rings C

- Air Nail Gun

- 21 Framing Nailer SRN9021L

- Brad Nail Gun

- Roofing Nail Gun

- Pneumatic Staple Gun

- Finish Nail Gun

- Concrete Nailer

- Hog Ring Gun C

- Siding Nail Gun

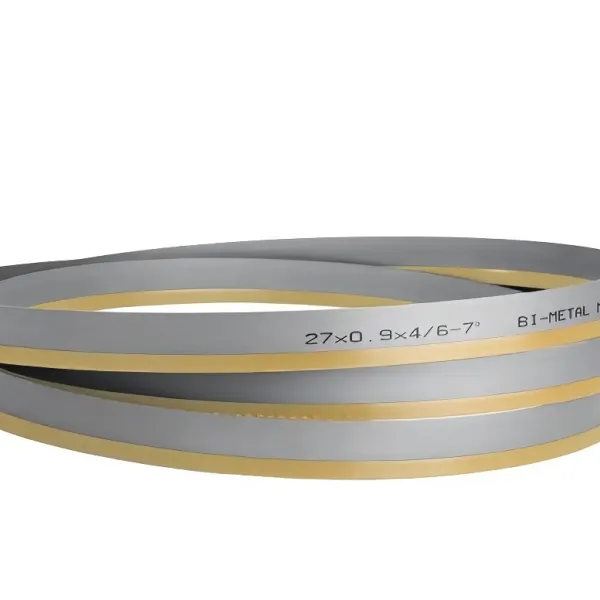

What are you looking for?