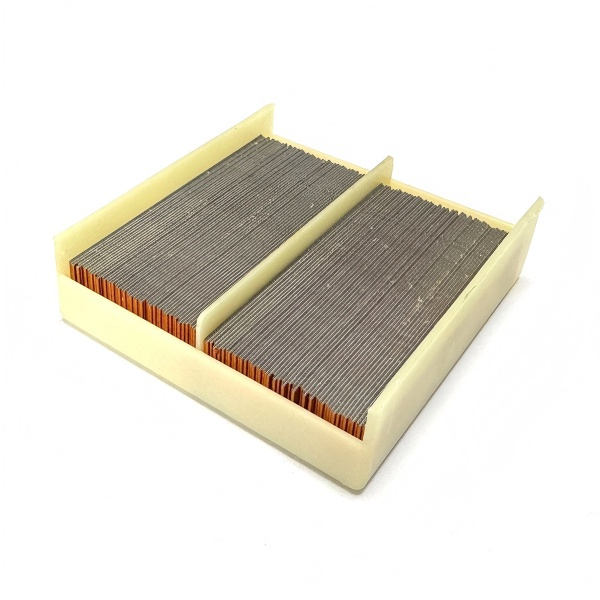

Driving nails into concrete is a challenging yet essential task often encountered in construction and home improvement projects. Concrete nails offer a reliable solution for securing materials such as wood and metal into concrete surfaces. This comprehensive guide will cover the tools and methods required, the selection of suitable nails—such as positive placement nails for precision fastening—a step-by-step guide to executing the task successfully, and safety measures to ensure your wellbeing. Additionally, it addresses common issues faced during the process, helping you navigate through complex barricades with ease. Whether you're working with concrete or collated drywall screws, understanding these fundamental techniques can significantly enhance your efficiency and precision.

Tools and Methods

To drive nails into concrete effectively, specific tools and techniques must be employed. Traditional hammering methods are often insufficient due to the hardness and density of concrete. Therefore, specialized tools such as framing nail guns, pneumatic concrete nailers, and concrete nail drivers are indispensable.

Tool Type | Description | Application |

Framing Nail Gun | Uses pneumatic power to drive nails into hard surfaces | Framing and heavy-duty jobs |

Pneumatic Concrete Nail Gun | Designed for concrete surfaces with higher pressure | Securing heavy materials to concrete |

Concrete Nail Driver | Manual tool for driving concrete nails | Smaller projects, precise placement |

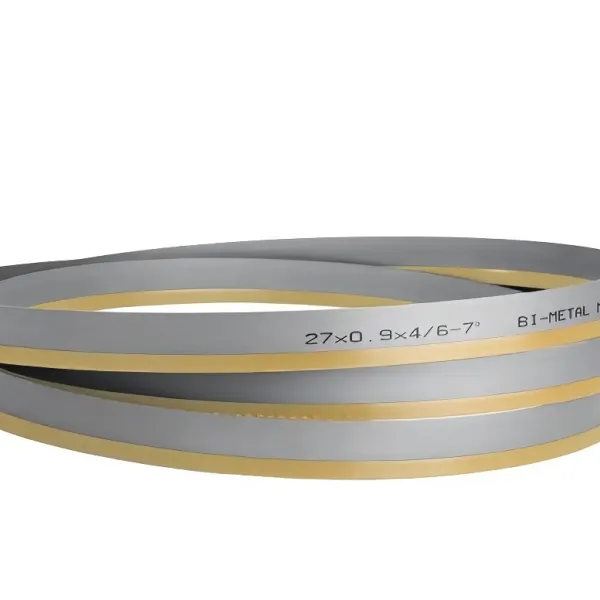

Aside from these tools for concrete, a rotary saw blade is useful for making precise cuts on materials that need to be attached to concrete. When accuracy and alignment are critical, positive placement nails combined with compatible nail guns help achieve more consistent and clean fastening results, particularly in detailed framing or anchor work. Choosing the right equipment ensures you can penetrate hard surfaces both safely and efficiently.

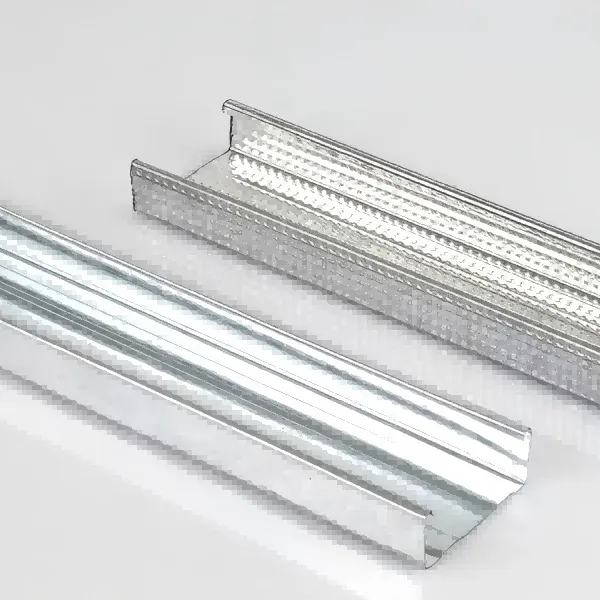

Nail Selection

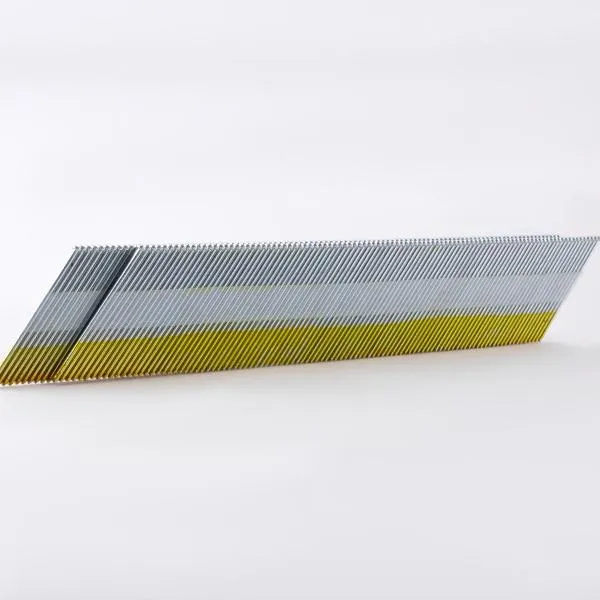

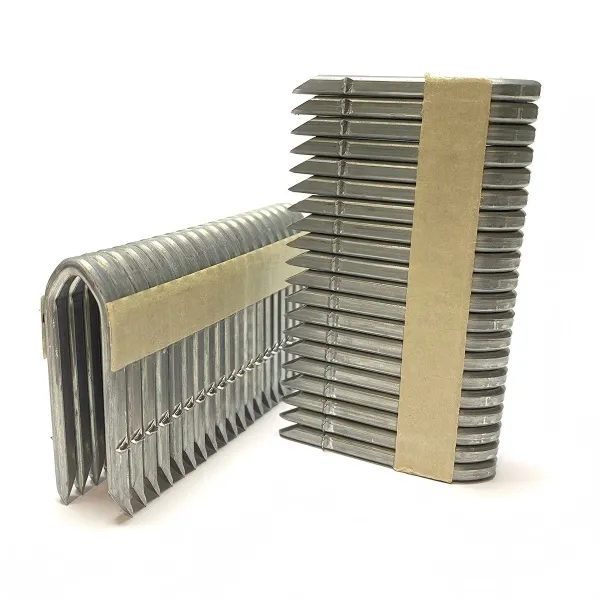

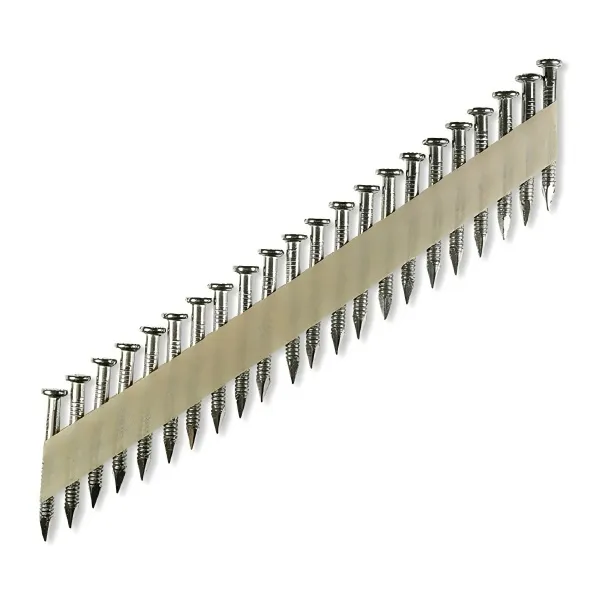

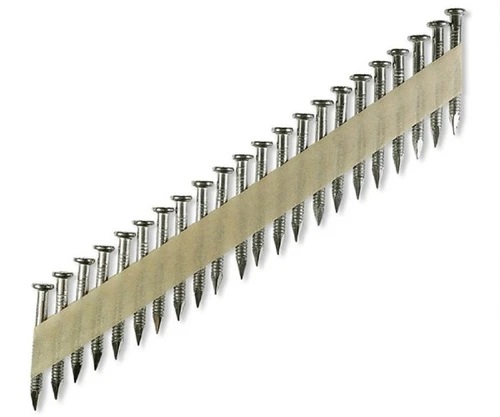

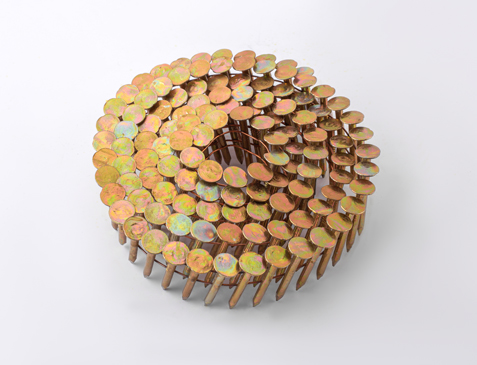

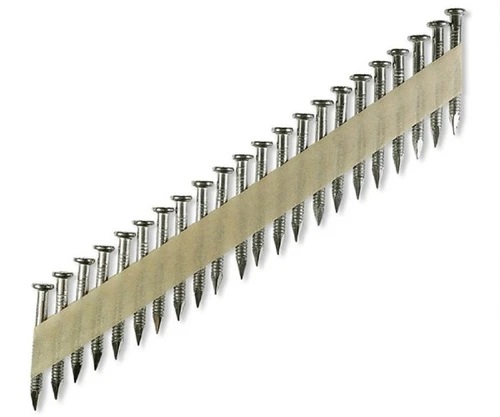

Selecting the right nails directly impacts how well they hold materials in place and resist stress. Galvanized steel roofing nails, ring shank coil roofing nails, and positive placement nails are among the most reliable options for their strength and rust-resistant properties, making them ideal for long-term projects in varying environments.

When working with concrete, positive placement nails stand out because they allow for controlled and accurate driving, especially when paired with framing or metal-connecting nail guns. For non-structural or temporary work, common nails may suffice; however, advanced construction projects benefit significantly from using roofing nail guns and positive placement nails to achieve secure, clean, and efficient fastening.

Step-by-Step Guide

Driving nails into concrete requires precision, patience, and the right sequence of actions. Follow these steps to ensure strong and stable fastening results:

Preparation – Clear the surface of debris and measure areas where nails will be placed.

Select Tools – Choose appropriate equipment such as a pneumatic framing nailer and prepare bulk nails or positive placement nails suited to your project.

Marking – Use chalk or a pencil to mark exact nailing points to prevent errors.

Drilling Pilot Holes – With a masonry drill bit, create holes slightly smaller than the nails to ease insertion.

Nailing – Use a nail and staple gun or positive placement nailer for precise driving, or a manual concrete gun for smaller-scale work.

Inspection – Check that each nail is securely embedded and flush with the surface.

Throughout the process, maintain steady control and alignment to prevent surface damage or nail bending.

Safety Measures

Concrete nailing involves potential hazards due to dust and the material's density. Adhering to proper safety precautions is crucial:

Wear protective goggles and a dust mask during drilling and nailing.

Use ear protection when operating pneumatic concrete nail guns.

Handle tools for roofing and air nail guns with care to avoid accidental discharge.

Maintain good posture and ergonomics when using heavy tools for long periods.

Following these safety guidelines—and using positive placement nails to reduce the need for rework or repeated driving—can significantly lower risks and improve project accuracy.

Common Issues

Several issues can arise when working with concrete, such as nail bending, incomplete penetration, or surface cracking. Common solutions include:

Adjusting power tool pressure settings to prevent nail damage.

Checking the concrete's hardness using black steel pipe testers to ensure structural integrity.

Using reinforced fasteners like galvanized roofing nails or positive placement nails for improved grip and strength.

Pre-drilling with reciprocating saw blades or masonry bits to reduce surface stress.

By recognizing and addressing these challenges, you'll be better equipped to perform reliable and damage-free installations.

Conclusion

While driving nails into concrete can be daunting, mastering the right tools, fastener types, and safety methods ensures professional results. Whether you're anchoring wood, steel, or decorative fixtures, selecting high-quality fasteners such as positive placement nails will enhance both precision and durability. By following these best practices and keeping your equipment in excellent condition, you'll achieve efficient, long-lasting, and structurally sound results in every project.