When it comes to selecting the right fastening solutions for outdoor applications, stainless steel screws and galvanized screws often top the list due to their robust performance in diverse environmental conditions. The choice between these two fastener types requires careful consideration of factors such as rust resistance, strength, cost, and suitability for specific applications. This article evaluates these aspects, providing an in-depth comparison to help you make an informed decision. Whether you are dealing with fencing staples or choosing the right types of fasteners for your project, understanding the benefits and drawbacks of each option is crucial.

Rust Resistance Comparison

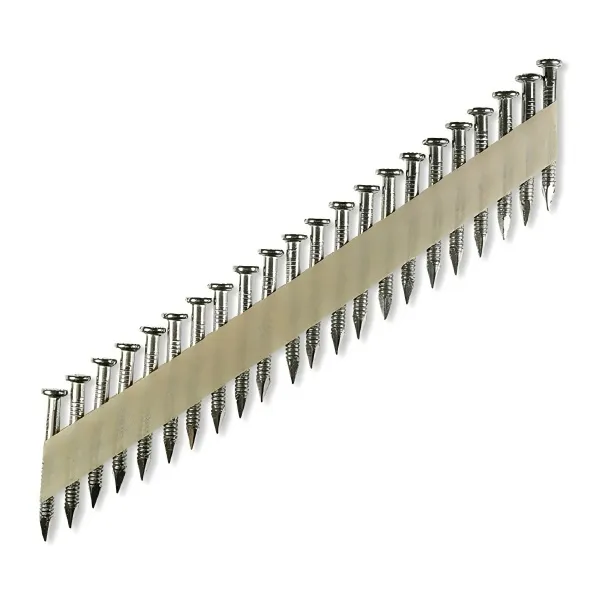

Rust resistance is a critical factor when choosing screws for outdoor use, as exposure to moisture and varying temperatures can significantly impact durability. Stainless steel screws are renowned for their excellent corrosion resistance, owing to their unique alloy composition that includes chromium, which forms a protective oxide layer. This makes them ideal for high-humidity areas or coastal regions where salt exposure is prevalent.

On the other hand, galvanized screws are coated with a layer of zinc that acts as a barrier against corrosive elements. While effective, this protection is generally less durable than stainless steel, especially in regions with extreme conditions. However, for short-term projects or areas with moderate weather patterns, galvanized screws can be a cost-effective choice.

Screw Type | Rust Resistance |

Stainless Steel Screws | High |

Galvanized Screws | Moderate |

Strength and Load Bearing

When considering strength and load-bearing capabilities, both stainless steel screws and galvanized screws have their merits, though they differ in performance according to the specific type of application. Stainless steel offers superior strength and ductility, allowing it to withstand higher load demands. The flexibility of stainless steel makes these screws less likely to snap under pressure, which is particularly beneficial in structural construction projects requiring a high degree of security and reliability, such as in industrial pipe furniture.

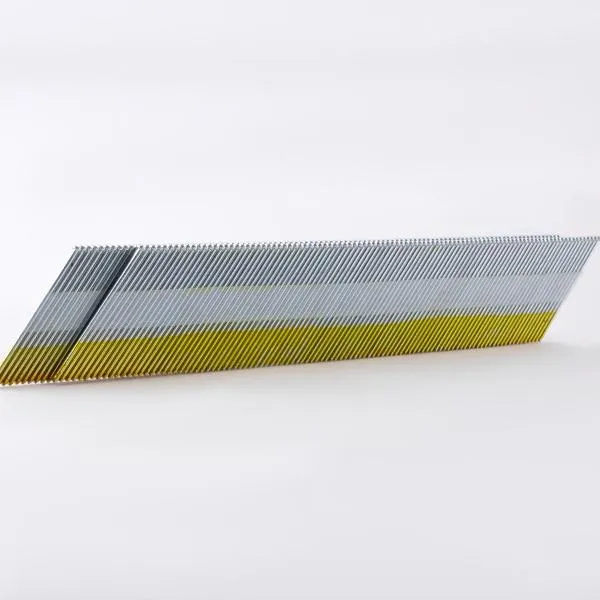

Meanwhile, galvanized screws retain satisfactory strength adequate for less demanding applications. The zinc coating can slightly compromise their load-bearing capacity in comparison to stainless steel, especially under fluctuating environments. However, for regular everyday tasks like securing roofing nail gun components or light framing nail gun tasks, galvanized screws can adequately meet the required strength standards.

Screw Type | Strength | Load Bearing |

Stainless Steel Screws | High | High |

Galvanized Screws | Moderate | Moderate |

Price Differences

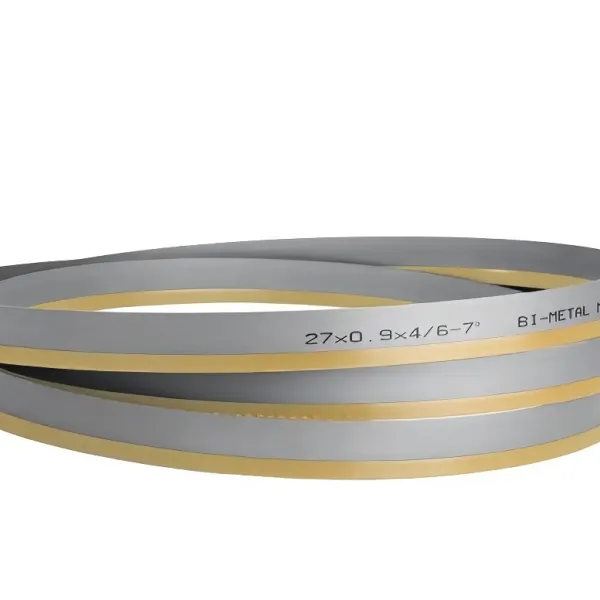

Price is a key consideration in selecting the appropriate screw for outdoor projects. Typically, stainless steel screws are priced higher due to their premium material composition and superior resistance to environmental factors. This solidifies their place as a long-term investment suitable for projects demanding durability over cost, such as metal roofing machine assembly or high-performance roofing machine installations.

Conversely, galvanized screws offer a more budget-friendly alternative that is suitable for projects with restricted financial scope. Their lower cost makes them exceptional for short-term applications or when handling a large volume of screws without compromising the overall budget. If you are undertaking widespread roofing tasks with galvanized steel roofing nails, galvanized screws provide a substantial cost relief.

Screw Type | Price Range |

Stainless Steel Screws | High |

Galvanized Screws | Low to Moderate |

Application Suitability

The suitability of screws for specific applications significantly influences their effectiveness and longevity. Stainless steel screws shine in environments demanding robustness and resilience, such as marine-based projects or outdoor furniture exposed to extensive moisture. The ability of these fasteners to withstand harsh conditions makes them ideal for securing black steel pipe structures or ensuring stability in culvert pipe installations.

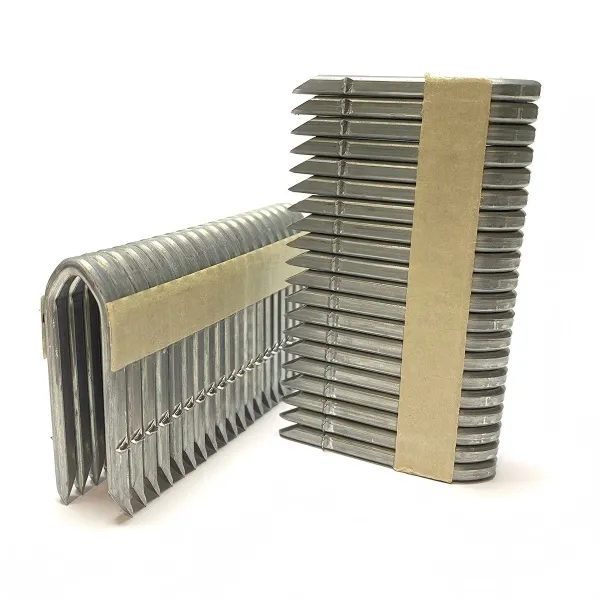

For tasks demanding economy alongside efficiency, galvanized screws emerge as viable contenders. They are particularly apt for everyday construction duties like securing wire staples in fences or applying stockade staples in garden setups. With their efficient zinc coating, these screws balance performance and cost, catering to less intensive outdoor applications like roofing with ring shank roofing nails or in roof panel machine setups.

Screw Type | Best Applications |

Stainless Steel Screws | Marine, High Moisture Areas |

Galvanized Screws | General Outdoor Construction |

User Testimonials

User experience provides valuable insights into the practical functionality and perceived value of stainless steel and galvanized screws. Many users praise stainless steel screws for their unmatched resistance to rust and reliability in long-term applications, particularly in projects like outdoor decking and fencing which must endure unpredictable weather conditions. Their feedback highlights satisfaction with the screws' performance despite the higher price.

On the other hand, users of galvanized screws often express appreciation for their cost-effectiveness and satisfactory performance in non-critical applications such as garden creations or weekend DIY projects. Their testimonies reveal contentment with the balance between price and functionality, making galvanized screws an attractive option when budget constraints are present.

Screw Type | User Feedback |

Stainless Steel Screws | Highly Resistant and Reliable |

Galvanized Screws | Cost-effective and Adequate for Light Use |

In conclusion, when selecting between stainless steel screws and galvanized screws for outdoor use, considering factors such as rust resistance, strength, cost, application suitability, and user feedback is essential. Stainless steel provides outstanding durability and reliability suitable for demanding projects, while galvanized options offer a budget-friendly alternative for less intensive tasks. Whatever your specific needs, understanding these aspects ensures an informed choice that aligns with your project's demands.