Fasteners are a critical element in construction, impacting the strength, durability, and safety of any project. Whether you're building a home, a commercial building, or a piece of industrial machinery, the right choice of types of fasteners can make all the difference. In this article, we will explore the basic categories of fasteners, their uses in framing and roofing, various material options, factors to consider when selecting them, and how to correctly store and handle these essential building components. By focusing on these areas, we aim to enhance your understanding, allowing you to make informed decisions for your construction needs, whether you're using an air finish nailer or ensuring concrete nails are tightly bonded in a structural setting.

Basic Fastener Categories

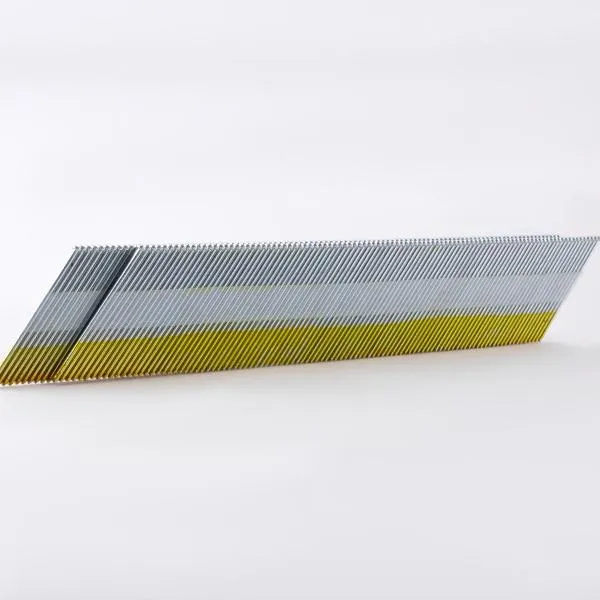

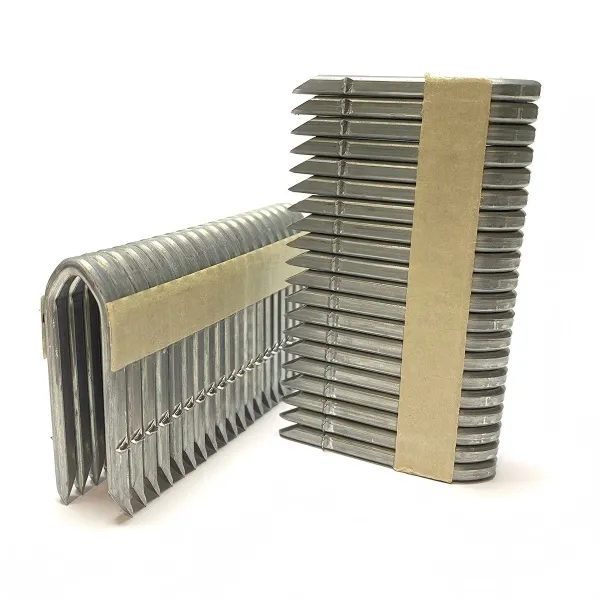

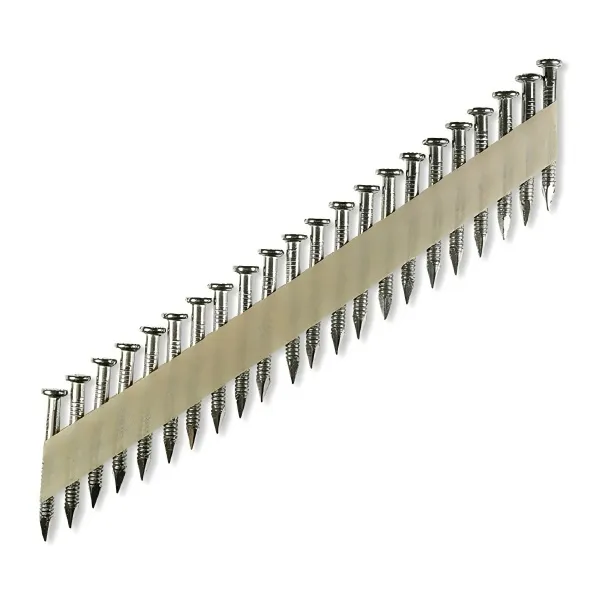

Construction fasteners come in numerous shapes and sizes, each serving a distinct function. The four broad categories include nails, screws, bolts, and staples. These tools offer various solutions depending on the specific demands of your project, whether you're installing drywall with a nail and staple gun or securing materials using collated drywall screws.

Category | Description | Common Use |

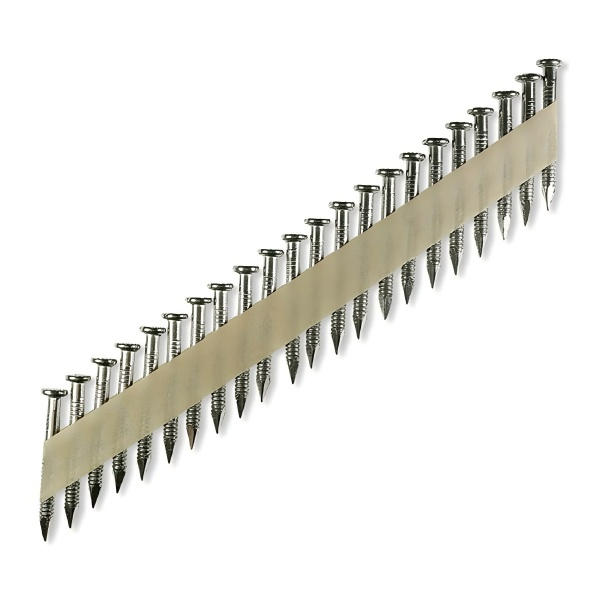

Nails | Simple metal pins driven into the material. | Used with tools like the pneumatic framing nailer or roofing nail gun for strong binding tasks. |

Screws | Fasteners with threads for a firm bite. | Common in tasks requiring high torque such as when using stainless steel screws in roofing. |

Bolts | Stronger screws with external threads. | Often used in conjunction with nuts for securing heavy items. |

Staples | U-shaped metal fasteners. | Used with air staple guns in applications like upholstery or lightweight wood frameworks. |

Uses in Framing and Roofing

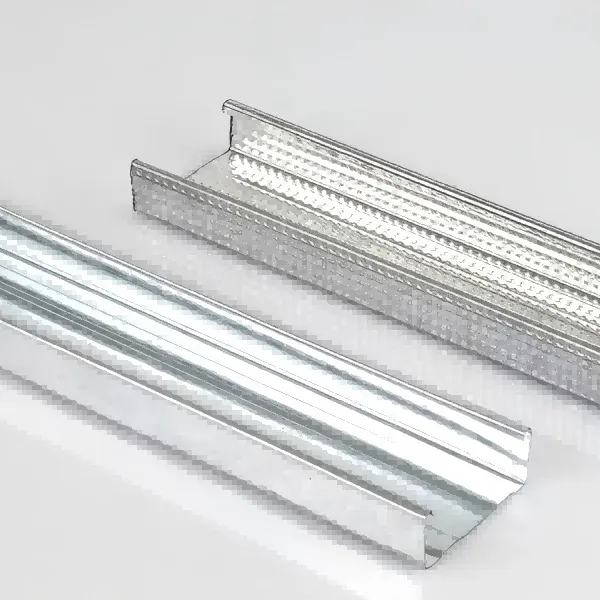

Framing and roofing are two construction areas heavily reliant on the appropriate fasteners for framing and roofing. Choosing the right roofing fasteners can prevent leaks and structural integrity issues. Framing nail guns are often employed to drive home long nails, ensuring stability and strength.

Application | Fastener Types | Considerations |

Framing | Common nails, joist hanger nails | Durability and strength are crucial for supporting structural loads. |

Roofing | Galvanized steel roofing nails, ring shank roofing nails | Weather resistance is vital to prevent corrosion and ensure longevity. |

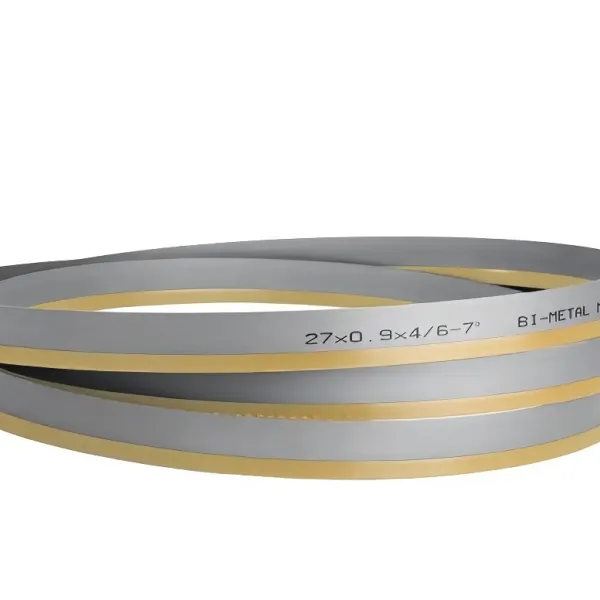

Material Options Explained

The material used in fasteners impacts not only their cost but also their performance under various conditions. Common choices include stainless steel, black steel pipe, and galvanized options, each offering distinct advantages and disadvantages.

Material | Advantages | Disadvantages |

Stainless Steel | High resistance to corrosion, ideal for outdoor applications. | Typically more expensive than other materials. |

Galvanized Steel | Cost-effective and offers some corrosion protection. | Less durable in highly corrosive environments. |

Black Steel | Strong and durable, often used in industrial settings. | Prone to rust if not coated properly. |

Selection Criteria

Several factors should influence the choice of fasteners, from the types of fasteners you need to the environment they will be used in. Understanding these criteria will guide you in making the best selection for your construction projects.

Environment: Consider whether the fasteners will be exposed to elements like moisture or chemicals, which requires using materials like stainless steel or galvanized options.

Load Requirements: Understand the load you need to support, which impacts the size and type, such as selecting hex cap screws for heavy-duty requirements.

Compatibility: Ensure compatibility with the tools being utilized—whether it's a concrete nail driver or a metal roofing machine.

Aesthetics: If appearance matters, such as in decorative fencing, opt for finishing tools that offer a visually appealing finish.

Storage and Handling Advice

Proper storage and handling of fasteners are essential to maintaining their integrity and effectiveness over time. Industrial staples and nails can corrode or lose their effectiveness if not stored correctly. Here are some guidelines:

Store fasteners in a dry, cool environment to prevent rust and deterioration. The use of industrial pipe furniture for organized storage could be beneficial.

Separate different fastener types to avoid cross-contamination of materials and ensure quick access.

Regularly inspect inventories for any signs of corrosion or damage, which can be particularly critical for galvanized roofing nails and fencing staples.

Conclusion

Choosing and using the correct types of fasteners is a blend of understanding their categories, applications, material options, and the appropriate handling and storage techniques. This ensures that any construction project, whether attaching wood with a pneumatic staple gun or reinforcing a roof with galvanized steel roofing nails, is durable, safe, and stands the test of time. Equipped with this knowledge, professionals and DIY enthusiasts alike can optimize their projects with confidence, knowing they have chosen the right fastener for the job.