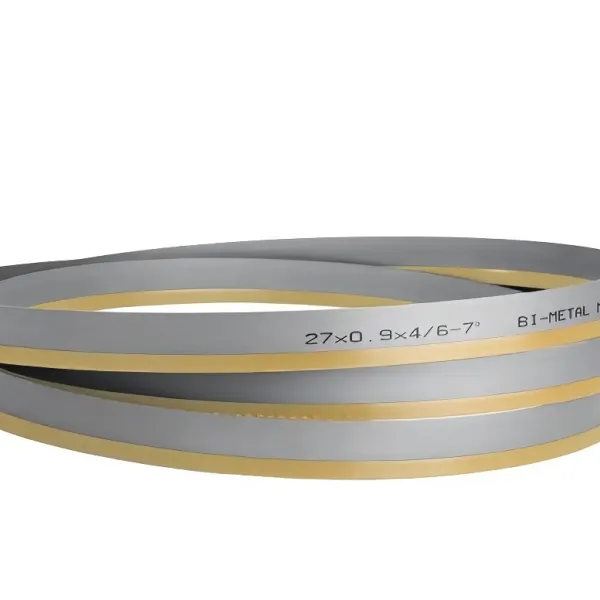

Sawmill bandsaw blades are versatile tools that can be used to cut a variety of materials, from wood to metal. Whether you're a professional woodworker or a DIY enthusiast, understanding how to use sawmill bandsaw blades safely is essential to protect yourself and ensure precision in your work. This article provides comprehensive insights into the setup instructions, blade tensioning, cutting techniques, necessary safety gear, and maintenance tips you need to operate sawmill bandsaw blades efficiently. Whether you are cutting wood with the perfect circular saw blade or managing precise cuts with specialized reciprocating saw blades, this guide is designed to make sure you achieve superior results while keeping safety at the forefront. By ensuring the proper use of sawmill bandsaw blades, you not only optimize their performance but also extend their lifespan.

Setup Instructions for Sawmill Bandsaw Blades

Setting up your sawmill bandsaw blades correctly is the first step in ensuring both safety and accuracy during operation. A well-prepared setup minimizes the risk of accidents and enhances cutting precision, whether you're dealing with delicate materials or robust components like steel pipe in China or black steel pipe. Proper setup involves the alignment and calibration of several parts, which we will delve into next:

Step | Action | Purpose |

1 | Level the base | Ensures stability and accurate cuts |

2 | Check the frame alignment | Prevents blade wobble |

3 | Install the blade | Proper blade installation avoids breakage |

4 | Adjust the guides | Maintains blade alignment and support |

5 | Secure the worktable | Provides a stable cutting surface |

Make sure that all adjustments are secure before you start cutting, as these will affect your safety and the quality of the cuts you make.

Sawmill Bandsaw Blades Tensioning

Blade tensioning is a critical aspect of using sawmill bandsaw blades. Incorrect tensioning can lead to blade drift, breakage, or inaccurate cuts, whether you are using sawmill blades or standard bandsaw varieties. The following sections explain how to achieve the optimal tension for your sawmill bandsaw blades:

Assess Blade Type and Size: Different materials and blade sizes require different tensioning levels. Check the manufacturer's guidelines for your specific blade, whether it's a rotary saw blade or a specialty type. Typically, blades require more tension for thicker or harder materials.

Adjust the Tensioning Mechanism: Most sawmill bandsaw blades come with a built-in tensioning gauge or knob. Spin this knob clockwise to increase tension or counterclockwise to reduce it. Aim for a tension that allows the blade to flex only slightly, similar to a guitar string's tightness.

Test for Optimal Tension: After adjusting, manually rotate the wheels. A well-tensioned sawmill bandsaw blade should stay centered and straight without pulling off the wheels or fluttering. Periodically check tension during large projects, especially those involving different material types, like steel profiles or concrete tools.

Proper blade tensioning not only enhances the safety and precision of your cuts but also extends the life of the sawmill bandsaw blades by reducing the likelihood of breakage.

Cutting Techniques for Sawmill Bandsaw Blades

Knowing the right cutting techniques ensures that you get clean, precise cuts every time, whether you are utilizing a framing nail gun to secure wood or dealing with durable materials like galvanized pipe suppliers. Here are the essential cutting techniques to master:

Resawing: Used for cutting thicker pieces into thin, even slices. Ensure your blade's width and tooth pitch suit the wood species and thickness.

Crosscutting: Cut across the grain for clean cuts on pallet tools or other wood projects. Use a smaller tooth blade for better results.

Curved Cutting: Best achieved with a narrow, flexible blade; perfect for intricate designs or furniture work. Low tension helps, so the blade can maneuver without breaking.

Ripping: Cut along the grain of the wood. Use a wide blade with fewer teeth for a faster but slightly rougher cut.

Each technique may require different sawmill bandsaw blades or setup adjustments. For example, resawing may demand more tension and a wider blade, while curved cutting benefits from a thinner blade.

Safety Gear

Safety is paramount when operating potentially dangerous machinery, such as sawmill bandsaw blades. It's crucial to gear up properly to prevent accidents while performing tasks like cutting with band saw blades for sale or handling metal tasks with tools for drywall. Here are the fundamental pieces of safety equipment you need:

Safety Glasses: Protects your eyes from flying debris, especially when cutting metals or fence post staples that might send off sharp shards.

Hearing Protection: Sawmill bandsaw blades can be noisy, making earplugs or earmuffs necessary.

Gloves: Protect your hands, but make sure they are snug to avoid getting caught in the blade.

Dust Mask: Prevents inhalation of fine particulate matter when cutting wood, especially treated varieties.

Proper Footwear: Steel-toed boots provide toe protection from dropped materials or devices.

Safety gear not only reduces the risk of injury but also allows you to focus more on achieving the perfect cuts.

Maintenance of Sawmill Bandsaw Blades

Regular maintenance of your sawmill bandsaw blades enhances their longevity and performance, ensuring they're always ready for action, whether you're using them on black metal pipe or performing intricate cuts for industrial pipe furniture. Here's a checklist to keep your blades in top shape:

Clean the Blade: Remove debris and resin build-up that can affect cutting efficiency and cause blade damage.

Lubricate Moving Parts: Keeps the machine running smoothly. Use a lubricant suitable for high-friction parts.

Check for Wear and Tear: Regular inspections can spot issues in components, particularly around the guide bearings and wheel alignment.

Replace Worn Components: Prompt replacement of worn-out blades and guides prevents unexpected downtimes and complex machinery damage.

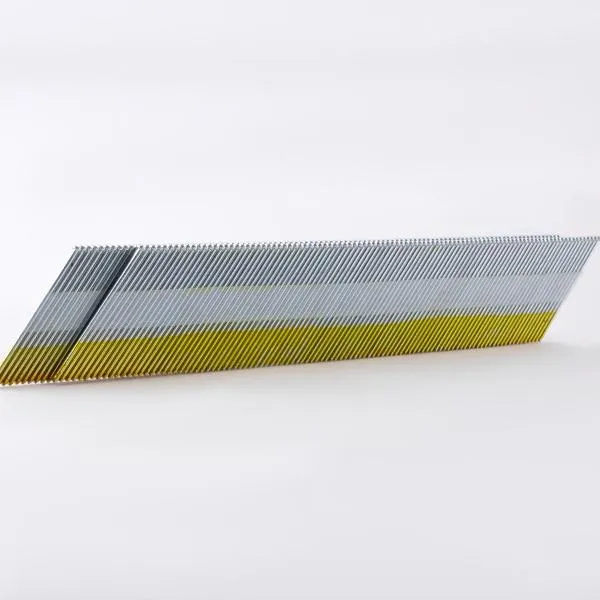

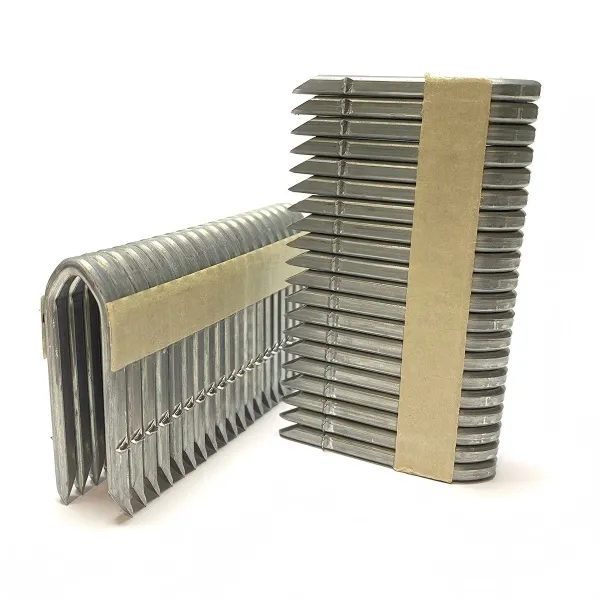

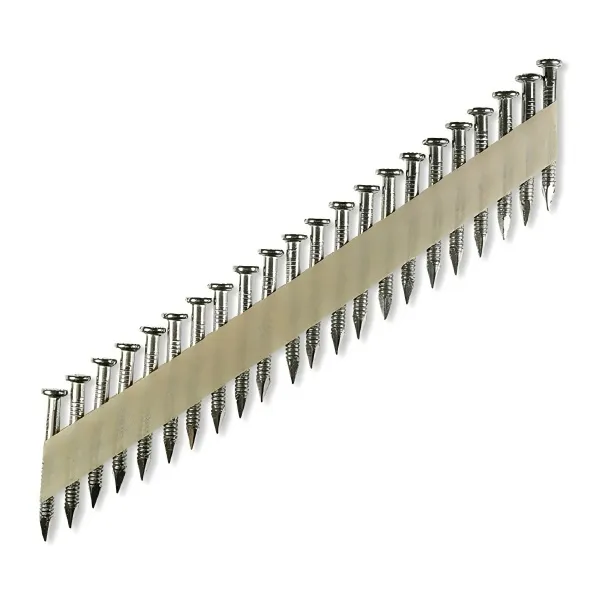

Regular maintenance practices will ensure consistent performance, safety, and extend the life of sawmill bandsaw blades and their components, such as ensuring stainless steel finish nails and industrial staples can still efficiently penetrate target materials.

Conclusion

Using sawmill bandsaw blades safely and effectively involves mastering setup, understanding blade tension, honing cutting techniques, adhering to safety protocols, and committing to regular maintenance. Whether you're a novice or a seasoned professional, these guidelines ensure you achieve precision while safeguarding your well-being. Investing in quality sawmill bandsaw blades and ensuring proper upkeep can further enhance your projects' outcomes, keeping both you and your tools in top-notch condition.