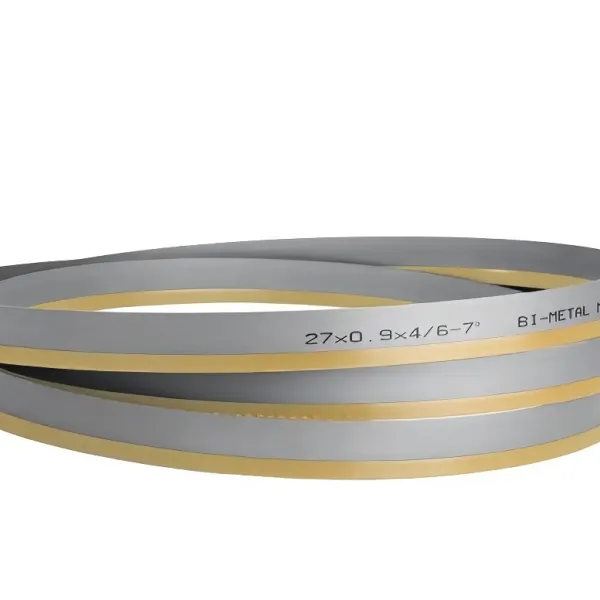

Symbol for Surface Treatment

1. Passivation 2. Oil painting 3. Coating 4. Parkerising 5. No processing

(1) Passivation: The galvanizing layer can be passivated to reduce the Folding rust (white rust) under the condition of storage and transportation. However, the corrosion resistance of this chemical treatment is limited and hinders the adhesion of most coatings. This treatment is generally not used in zinc and iron alloy coating, in addition to the smooth surface, as a routine, other types of galvanized coating are passivated in the factory.

(2) Oil painting: Oil coating can reduce the corrosion of steel plate under the condition of wet storage and transportation. The passivated steel plate and steel strip will be coated with oil to further reduce the corrosion under wet storage conditions. The oil layer should be able to be removed with a degreasing agent that does not damage the zinc layer.

(3) Coating: By coating a very thin transparent organic coating film, an additional anti-corrosion effect is provided, particularly the fingerprint resistance. It can improve lubricity during molding and act as adhesive base for subsequent coating.

(4) Parkerising: Through phosphating treatment, various coating types of galvanized steel plate, in addition to normal cleaning, no further treatment can be coated. This treatment can improve the adhesion and corrosion resistance of the coating and reduce the risk of corrosion during storage and transportation. After phosphating with suitable lubricant, the molding performance can be improved.

(5) No processing: Steel plates and steel strips supplied in accordance with this standard may not be surface treated by passivation or coating or phosphating unless the orderer has requested and is responsible for such non-treatment.