(1) Before installing the steel bellows culvert body, check the flatness, level, and elevation of the bottom foundation of the culvert; determine the location, central axis, and midpoint of the culvert.

(1) Before installing the steel bellows culvert body, check the flatness, level, and elevation of the bottom foundation of the culvert; determine the location, central axis, and midpoint of the culvert.

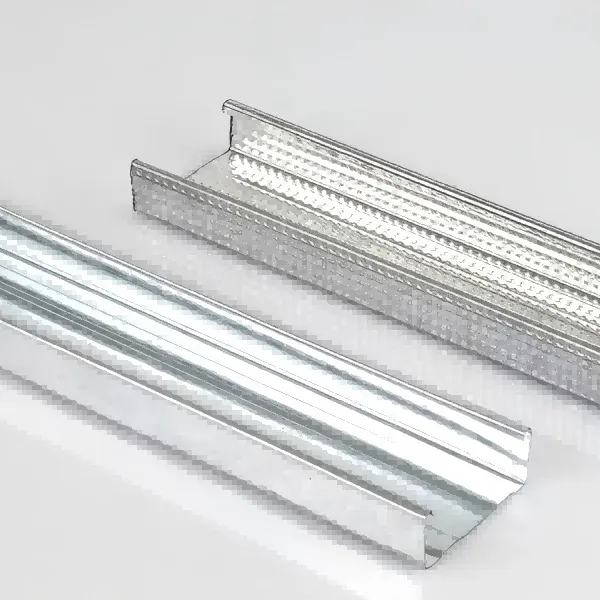

(2) Connect and install steel culvert pipe, and discharge the culvert according to the actual situation of the culvert.

If the water inlets and outlets on both sides of the culvert are oblique openings with the same slope as the roadbed, install the middle pipe section first during installation, and leave the water inlets and outlets in the length direction of the foundation. After all the middle pipe sections are installed, install the water inlet and outlet on both sides after correcting them in place.

When installing, discharge the first pipe section from one side so that the center of the pipe is parallel to the longitudinal centerline of the foundation, and also put the second pipe in place. When the gap between the adjacent flanges of the two pipes is 3~5cm, Use a small crowbar to align the bolt holes on the flange so that the bolt holes on the two pipe flanges are aligned. At this time, use the crowbar to pry the pipe section from the other end of the second pipe section to make it translate longitudinally. Make the distance between the two flanges about 2cm, then put on all the bolts, screw on the screws, and bring flat buckles.

After that, they are connected section by section in this way, and the middle pipe sections of each culvert have no order and can be connected at will.

(3) Asbestos-inlaid mats, due to the terrain and other reasons, sometimes the distance between two adjacent flanges is small. At this time, use a hammer and chisel to cut a gap of about 1 cm between the two flanges, and use a screwdriver to place the asbestos mat It is inserted between the two flanges. Sometimes the distance between the two flanges on the top of the pipe is large, and the asbestos pad is difficult to inlay. The asbestos pad is fixed to the bolt with a tie wire, and then the worker starts to tighten the screw symmetrically. There is only a gap of 2-3mm between the two flanges from the outside.

(4) The installation of the water slope on the surface of each pipe section is smooth, the pipe section must be cushioned firmly, and no debris such as soil shall be left in the pipe. The roundness and position of the pipe section are corrected every two sections are installed. If there is a deviation, use a jack to correct the deviation of the upper pipe section in the direction of the deviation.

(1) Before installing the steel bellows culvert body, check the flatness, level, and elevation of the bottom foundation of the culvert; determine the location, central axis, and midpoint of the culvert.

(1) Before installing the steel bellows culvert body, check the flatness, level, and elevation of the bottom foundation of the culvert; determine the location, central axis, and midpoint of the culvert.