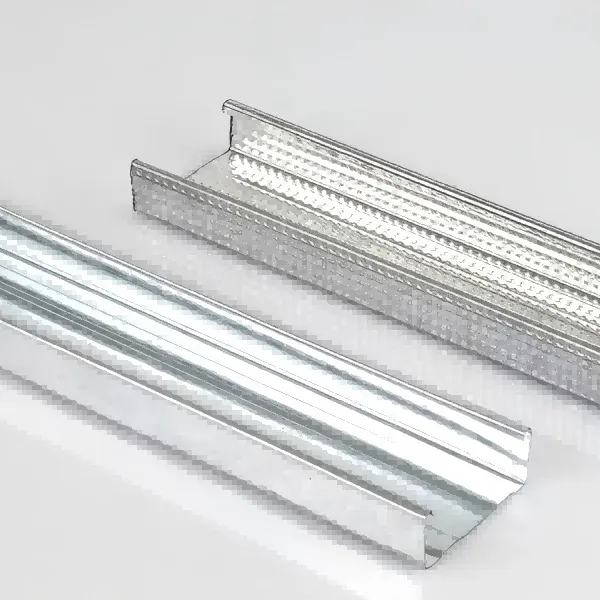

1. In wet and rainy areas, galvanized coil is more resistant to corrosion than Galvalume Steel Coil. Once a point of Galvalume Steel Coil is corroded, if no measures are taken in time, the corrosion area will be larger and larger, and even the whole plate surface. And galvanized coil even if a point of corrosion will not spread.

1. In wet and rainy areas, galvanized coil is more resistant to corrosion than Galvalume Steel Coil. Once a point of Galvalume Steel Coil is corroded, if no measures are taken in time, the corrosion area will be larger and larger, and even the whole plate surface. And galvanized coil even if a point of corrosion will not spread.

2. The cost of Galvalume Steel Coil is higher than that of galvanized coil. Galvanized coil without flowers, Galvalume Steel Coil with flowers.

3. Galvalume Steel Coil is cut, cut off the edge of the basic loss of protection will soon rust, so the aluminum zinc plate should be cut as little as possible, once cut after the application of anti-rust paint or zinc-rich paint to protect the edge, to be able to extend the service life of the plate.

4. Galvalume Steel Coil is aluminum-silicon alloy coated steel plate, in which the content of aluminum is 90%, silicon 10%.

5. Corrosion resistance: Color coated Aluminum> Galvalume Steel Coil> Galvanized coil.

6. Color coated Aluminum is also very few, mainly TDC51D, but subdivided into the main, according to the different substrate galvanized substrate, aluminum zinc substrate. Substrate coatings from 80g--280g are available. According to the surface color classification is more, common white gray, sea blue milky white, sky blue, Ivory white and so on.

7. The surface of galvalume steel coil than galvanized coil to beautiful, at the same time, the price of galvalume steel coil than galvanized coil more expensive, the price of small zinc flowers than large zinc flowers expensive.

1. In wet and rainy areas, galvanized coil is more resistant to corrosion than Galvalume Steel Coil. Once a point of Galvalume Steel Coil is corroded, if no measures are taken in time, the corrosion area will be larger and larger, and even the whole plate surface. And galvanized coil even if a point of corrosion will not spread.

1. In wet and rainy areas, galvanized coil is more resistant to corrosion than Galvalume Steel Coil. Once a point of Galvalume Steel Coil is corroded, if no measures are taken in time, the corrosion area will be larger and larger, and even the whole plate surface. And galvanized coil even if a point of corrosion will not spread.