| Pneumatic Nail Gun Model Comparison Table (CN55 - CN100) |

| Comparison Aspect | CN55 Nail Gun | CN70 Nail Gun | CN80 Nail Gun | CN90 Nail Gun | CN100 Nail Gun |

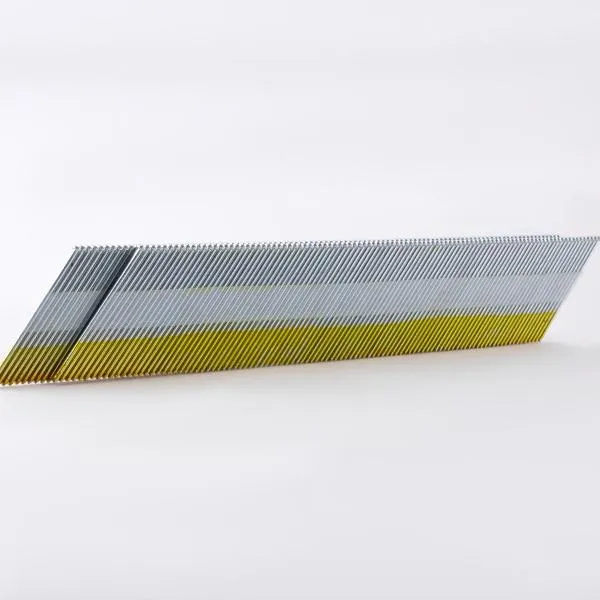

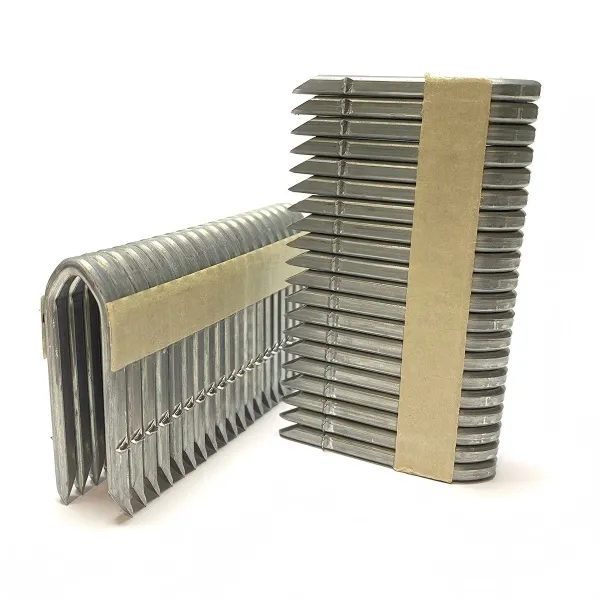

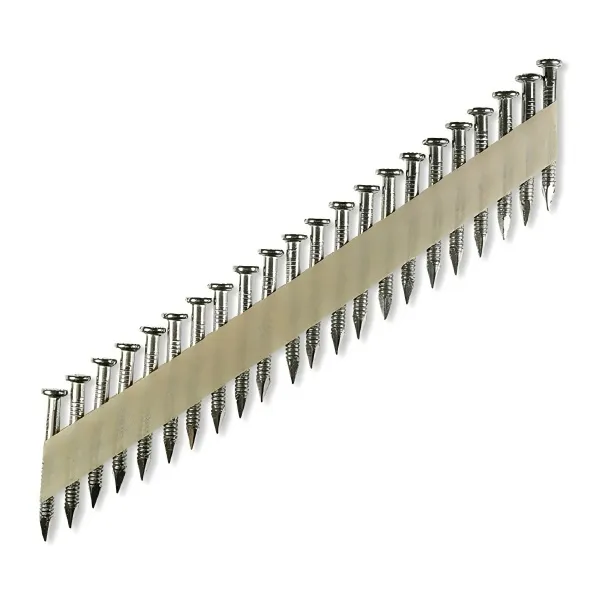

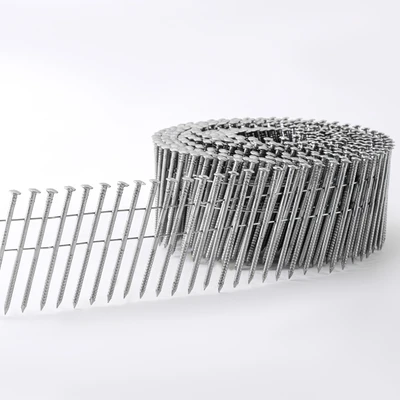

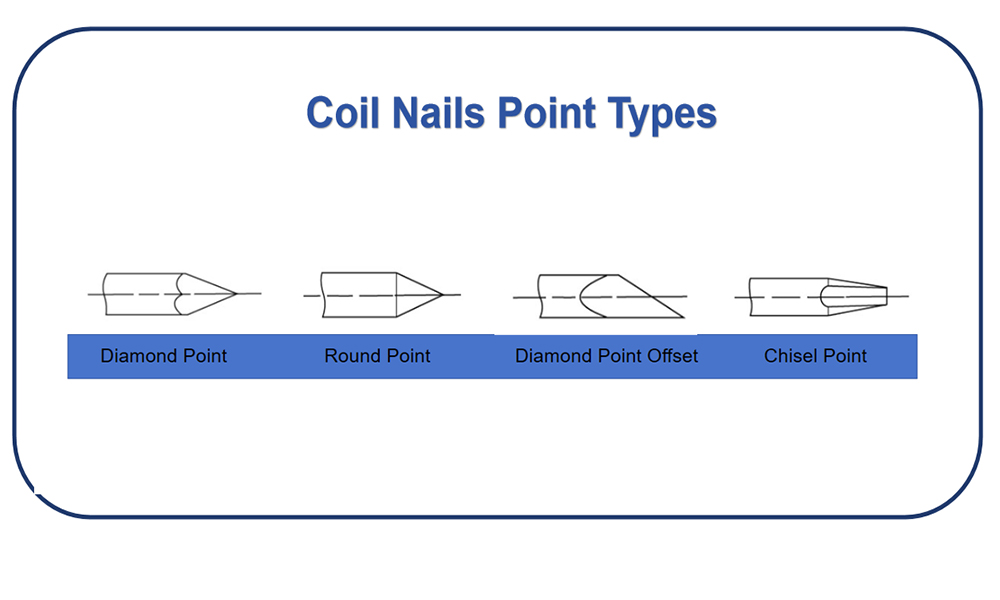

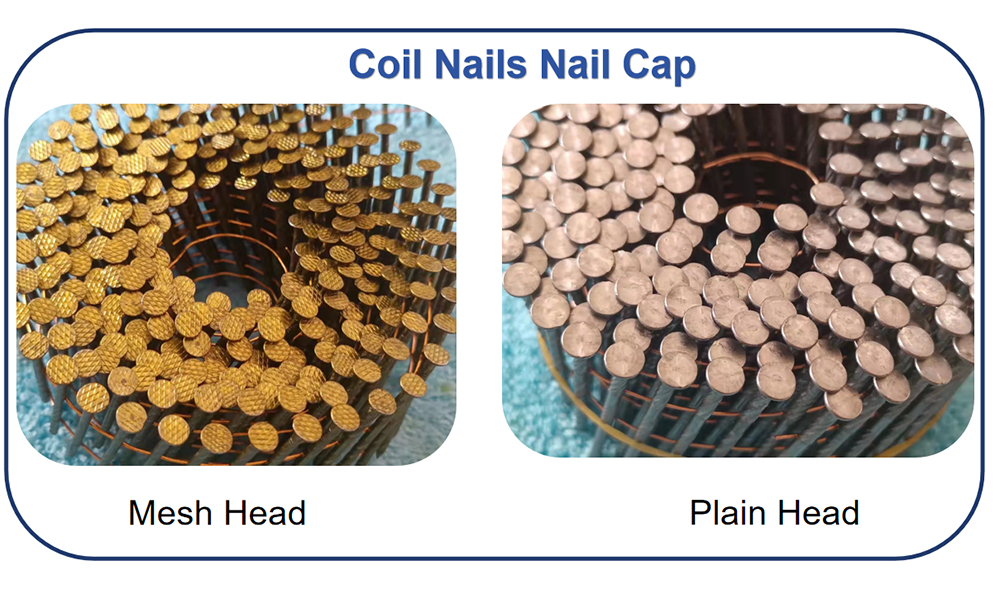

| Compatible Nail Specification | Type: Coil Nail | Type: Coil Nail | Type: Coil Nail | Type: Coil Nail | Type: Coil Nail |

| Wire Gauge: Finest | Wire Gauge: Fine | Wire Gauge: Medium | Wire Gauge: Thick | Wire Gauge: Thickest |

| Length: Shorter (e.g., 25-50mm) | Length: Medium (e.g., 45-70mm) | Length: Medium to Long (e.g., 50-83mm) | Length: Long (e.g., 50-90mm) | Length: Longest (e.g., 64-100mm+) |

| Typical Applications | Fine woodworking, furniture assembly, decorative trim, shelf pinning, picture frames | Wooden crate packaging, light framing, subflooring, decorative projects | Pallet making, wood framing, fencing, roof battens, container flooring | Heavy-duty crates, construction framing, shelving unit assembly, pallet repair | Extreme-duty crates, construction, beam connections, applications requiring highest tensile strength |

| Power Requirements | Low | Medium | Medium-High | High | Very High |

| Small capacity compressor sufficient (e.g., 2-3HP, 25-50L) | Requires stable air pressure (e.g., 3-4HP, 50L+) | Requires higher CFM and stable pressure (recommended 4HP+, ~100L) | Requires a high-CFM compressor and higher air pressure | Requires large industrial compressor with ample air supply |

| Weight & Size | Lightest & Most Compact | Lightweight | Medium / Heavy | Heavy | Heaviest |

| Easy for one-handed operation, ideal for detailed work | Slightly larger than CN55 but still portable | Significantly larger and heavier, requires some physical strength | Large body, noticeable recoil, often requires two hands for stability | Industrial-grade size and weight, strenuous to operate, typically requires two hands |

| Price Range | Low | Low to Medium | Medium | Medium to High | High |

| Key Characteristics | High precision, small nail marks, less likely to split wood, highly maneuverable. | Good versatility, balances strength and flexibility, a common industrial-grade entry choice. | The best balance of power and versatility, handles most heavy-duty woodworking tasks, very widely used. | High-power, designed for high-strength connections, strong penetration and holding power. | Top-tier power, for the most demanding applications, offers the highest nail tensile and shear strength. |